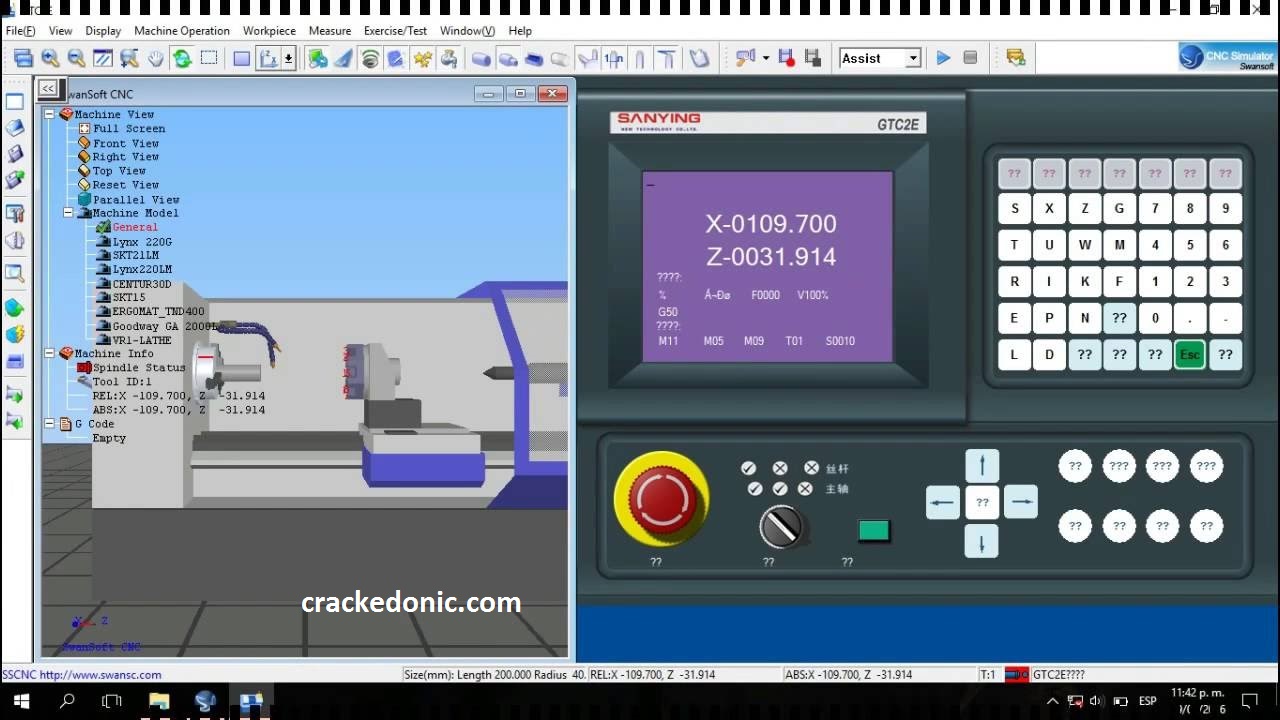

ScreenShots:

Software Description: Swansoft CNC Simulator v7.2.2.0 Crack

3.6 on 328 votes. The idea of the new CncSimulator is to provide the machining industry with a contemporary competent Fanuc-like CNC ISO simulator. Here you will find the famous CNCSimulator Pro software. It is a contemporary and advanced but easy to use CNC simulation system with a virtual CNC controller and various machines as well as the integrated CAM system SimCam. SSCNC is a real time 3D CNC simulator that uses OpenGL for fast and accurate 3D rendering modeling. Dynamic rotation, zoom, pan, full screen and switch views during simulation in real time. Program Editing. Programs are easily created in ASCII format using any text editor. Edition capabilities (cut, copy, paste), numbering and renumbering of lines.

Swansoft CNC Simulator is real-time 3D CNCmachine system simulation and advanced G-code verificationsoftware. It allows the user to simulate all the CNC machineoperations and debug NC code using the same platform!

2D and 3D simulation

– SSCNC is a real time 3D CNC simulator that uses OpenGL for fastand accurate 3D rendering modeling.

– Dynamic rotation, zoom, pan, full screen and switch views duringsimulation in real time.

– Realistic control panels and operator panels.

– Realistic three-dimensional numerical control machine tools andcontrol panel.

– Cutter trace simulation.

– Supports multiple monitors.

– Total machining process simulation: selecting the workpiece,zeroing the workpiece, select and measure tools, select the rightoperation mode for the machine and clearing all the alarms.

– Machine simulation includes real components like coolant, soundfor machining operations and chips generation.

– Workpiece setting and mounting. Allows to setup zeros and tooloffsets and the use of different clamping devices.

– Three-dimensional measuring of workpiece after it ismachined.

– Roughness measurements based on tool cutting parameters.

– Materials library, edit and insert new materials.

– Database management tools and tools customization.

– The turret can be configured for 4, 8 or 12 stations (front orrear). The automatic tool changer for the machining center can besetup horizontally or vertically.

– Use virtual measuring tools: edge finder, feeler gauge,micrometer, calipers etc.

– Windows MACRO recording and playback system.

– Operation process recording and replay in AVI format.

Program Editing

– Programs are easily created in ASCII format using any texteditor.

– Edition capabilities (cut, copy, paste).

– Numbering and renumbering of lines.

– Changes in the lines of program are simple and intuitive.

– Help on screen for G/M codes.

– Program verification of canned cycles and language syntaxaccording to the command code for the specific model.

Advanced programming functions

– G Code parser. Support ISO-1056 preparatory function codes (Gcodes), assistant function codes (M codes).

– G-code debugging tool.

– Capability to simulate canned cycles, macros and the inclusion ofparameters.

– FANUC, SIEMENS polar coordinate programming, G02, G03 spiralinterpolation.

– Support for custom code and cycles in different NC systems.

– Simulates post processed files produced by UGS, Pro-E, MasterCAM.

Operation of CNC machine

– Preset zero point G54, G55, G56, G57 etc …

– Preset tool axes X and Z (Lathe) and height of tool(Milling).

– Electronic hand wheel available.

– Modes JOG, MDI, EDIT, SINGLE BLOCK, AUTOMATIC, DRY RUN, STOPCYCLE, CYCLE START, EMERGENCY etc …

– Adjust the cooling hose.

– Alarm collision with the piece, bench or other machine parts.

– Adjust the parameters of the virtual machine.

– Performs all functions of the command operation, facilitating theadaptation of the student with the CNC equipment.

Cnc Simulator Pro Software

SSCNC Server Features

When the software is installed on a local network in aserver-client configuration it provides the instructor with thecapability for managing students, classes and tests. The followingfeatures are available:

1. Users management

Students are registered in the SSCNC server by means of a usernameand password. Once the student log in from any computer in a localnetwork the instructor can centrally manage, monitor and tutor thestudents.

Cnc Simulator Pro Download

2. Exercises management

Add and edit exercises in SSCNC server. Transmit exercisesincluding pictures to clients (students). Students work on theexercise and transmit the answers back to the instructor.

3. Network Monitor

SSNC sever saves students registration information and allowsquerying and controlling login, logoff and machine operations.Broadcast screen information to the students and remotely assistthem via remote view and controlling of the client PC.

4. Examination subsystem

Includes question library management, test paper management, thetest process management as well as the examination paper automaticgrading.

5. Test Administration subsystem

Including test data management, exam permit management and testresults management.

Installer Size: 412 MB

Download Links : Swansoft CNC Simulator v7.2.2.0 Full Crack

License agreement

UPON ACCEPTANCE OF THIS SOFTWARE EVALUATION LICENSE AGREEMENT (THE 'AGREEMENT'), CNCSimulator.com GRANTS TO THE REQUESTER A LIMITED NON-EXCLUSIVE LICENSE TO USE CNCSIMULATOR SOFTWARE AND DOCUMENTATION (THE 'SOFTWARE') AS FOLLOWS:

LICENSE:

Following download, Licensee may install and use the Software solely for installation on the computer system. Licensee may make one copy of the Software for backup purposes. Licensee shall not remove any copyright notices or other proprietary notices from the Software, and Licensee must reproduce such notices on all copies or extracts of the Software. The conditions for using the Software free of charge are stated on the web page of the Software (the Home Page of the CNCSimulator). The Licensee understands that these conditions can be changed at any time and that CNCSimulator.com has rights to change the price for the Software as well as the conditions at any time and without further notice.

OWNERSHIP:

The Software is owned by CNCSimulator.com, and is protected by copyright laws. Licensee acquires only the non-exclusive right to use the Software, at no charge for the time period specified on the web page of the Software, and does not acquire any right of ownership in the Software.

RESTRICTIONS:

It is understood by Licensee that the Software is made available only on the condition that the Software will not be modified in any way or otherwise transformed into any other form. Licensee shall not modify, translate, reverse engineer, decompile, or disassemble the Software or any portion of the Software. Licensee shall not distribute or create derivative works based on the Software. Licensee shall not duplicate in any form, except for archival purposes or for purposes necessary for the use of the Software for educational or investigational purposes, the Software, program statements or any other materials relating to the Software supplied by CNCSimulator.com, to Licensee.

WARRANTY DISCLAIMER:

The Software is provided on an 'as is' basis, without warranty of any kind, including without limitation the warranties of merchantability, fitness for a particular purpose and non-infringement. CNCSimulator.com, does not warrant that the Software will meet Licensee’s requirements, nor does it warrant that the operation of the Software be error-free. Licensee agrees to assume the responsibility to take adequate precautions against damages to Licensee’s operations which could be caused by defects or deficiencies in the Software.

LIMITATION ON LIABILITY:

NEITHER CNCSimulator.com NOR ITS LICENSORS SHALL BE LIABLE FOR ANY LOSS OR DAMAGE HEREUNDER, INCLUDING, WITHOUT LIMITATION, ANY INACCURACY OF DATA, LOSS OF PROFITS OR INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES INCLUDING NEGLIGENCE, EVEN IF SUCH PARTY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. SOME JURISDICTIONS DO NOT ALLOW THE LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES SO THIS LIMITATION MAY NOT APPLY.

SUPPORT:

The Software is provided on an 'as is' basis. CNCSimulator.com is not obligated to render any technical assistance or support in the use or operation of the Software or to correct or fix any defects or bugs in the Software. Although CNCSimulator.com appreciates any comments received from Licensee regarding the performance of the Software, CNCSimulator.com is under no obligation to respond to such comments.

EMAILS:

By installing and using the Software, the Licensee accepts that CNCSimulator.com will send reminders about the license as well as occasional offers, info mails etc. If the Licensee do not want to receive these emails he can turn them off by logging in to his account. If the Licensee do not want to receive any emails whatsoever he shall not install the software.

TERMINATION:

License to use the Software automatically terminates when the license issued by CNCSimulator.com expires. Upon termination, Licensee will promptly discontinue use of and destroy all copies of the Software then in Licensee’s possession or control. In addition, CNCSimulator.com may at its option terminate this Agreement upon notice to Licensee. All disclaimers of warranties and limitations of liability shall survive any termination of this Agreement.

BY AGREEING TO THE ABOVE CONDITIONS, LICENSEE ACKNOWLEDGES THAT LICENSEE HAS READ, UNDERSTANDS AND AGREES TO BE BOUND BY THE TERMS AND CONDITIONS OF THIS AGREEMENT AND THAT LICENSEE IS DULY AUTHORIZED TO DO SO.